The cultivation

The olive tree is an evergreen, long-lived, in fact, can live hundreds of years, more than 40 centuries. To flourish this plant requires a temperature below 7 ° for 2/3 months. The small flowers are called pinkies, and the fact mignolatura starts in March and April. The bloom takes place depending on the area from May to the first half of June.

Frantoio – Stages of processing olives in extra virgin olive oil

The harvest

During the olive harvest (October / November), the fields are full of whole peasant families and not, who spend entire days in contact with nature, in fact this kind of harvest is done by hand, and then it takes a lot of helps. The olives are made to fall from the tree on a cloth under the canopy, via the vibrator and vibration, in this way the olives fall on nets placed on the ground or even suspended, detachment of the olives is caused by subjecting the trunk and branches to the action of shakers that are attached with special clamps to the plant and make it vibrate until the olives disjoint from the branch and drop them.

In the meantime, the olives are taken to the mill to be dealt with. After the harvest, there are several stages before the olives become oil. First the olives are weighed, then they are washed. In the mill the processing steps will lead to Extra virgin olive oil of high quality.

The squeezing out

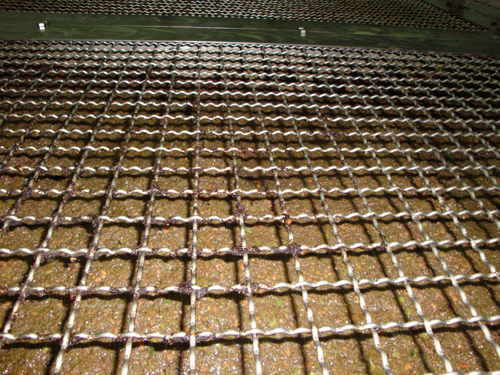

The first real transformation of the product inside the mill is the squeezing out: the olives are mechanically intact transformed into oily paste. There are two techniques :

• For pressure

Using granite millstones (from two to six elements) that operate for 20 30 minutes, this technique ensures a better dough preparation for the next squeezing.

• To centrifugation

They use metal crushers that can be of different type: hammer, discs, cones or roller.

Depending on the type and speed of centrifugation that lead to oils of different characteristics.

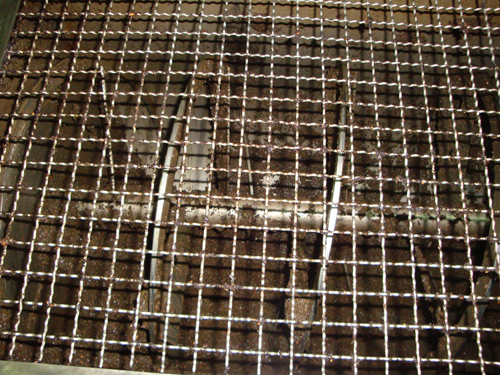

Gramolatura

This has the purpose to di-emulsify the oil present in the dough and to ensure that the small droplets of oil are aggregated between them. To achieve this it’s necessary to move in slow motion the pasta and heat the maximum permissible temperature that is around 25 °.

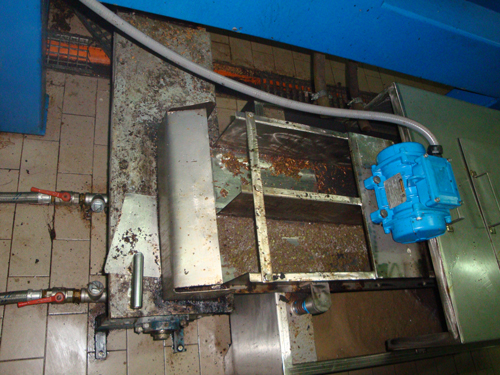

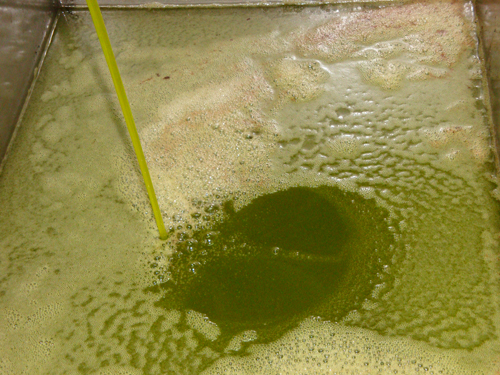

Decanter

Here, where the olives once crushed and transformed into paste, arrive at the centrifugal separator with horizontal axis, the decanter. These allows to separate between them the three phases present in the paste, water pomace oil, with different specific weight, by means of centrifugal force.

At this point they separate the oil from the pomace, a byproduct formed from the remnants of flesh and fragments of pits. The oil is then bottled and marketed.